Concrete Innovations: ICF vs. Shotcrete Panels, Precast, and 3D Printed Homes

Concrete Innovations:

ICF vs. Shotcrete Panels, Precast, and 3D Printed Homes

Concrete has moved beyond highways and high-rises. It’s now a leading choice for homeowners looking to build stronger, safer, and more energy-efficient homes. If you’re exploring alternatives to traditional wood framing, you’ve likely come across several concrete construction options.

Four of the most talked-about systems today are:

- Insulated Concrete Forms (ICF)

- Shotcrete Sandwich Panels

- Precast Concrete Panels

- 3D Printed Concrete Homes

Each one offers unique advantages, but they differ greatly in how they’re built and how they perform. Let’s walk through what sets them apart so you can make the right decision for your home and your long-term goals.

Insulated Concrete Forms (ICF): Tried, True, and Tornado-Tested

ICF homes are built using interlocking foam blocks that are stacked on-site, reinforced with steel, and filled with concrete. The foam stays in place, forming a double layer of continuous insulation around a solid concrete core.

This method offers the best of both worlds: high performance and proven reliability. A typical ICF wall includes six inches of steel-reinforced concrete, plus almost six inches of foam insulation, resulting in a wall that’s almost 12 inches thick overall. These walls are capable of withstanding winds up to 250 mph, making them strong enough to stand up to tornadoes.

ICF walls provide a nominal R-value of 23 with a performance R-value of 50. They reduce outdoor noise, eliminate air leaks, and maintain a comfortable interior temperature year-round. That performance translates into serious energy savings, especially in climates like the Ozarks with wide temperature swings between seasons.

Shotcrete Sandwich Panels: Powerful, But Precision-Dependent

Shotcrete sandwich panels flip the ICF concept inside out. Instead of pouring concrete into a form, this method starts with a foam core and applies concrete to both sides, often using a high-pressure spray. The concrete bonds to wire mesh or rebar grids, forming a rigid wall assembly around the insulating center.

When engineered properly, these walls can also resist wind loads up to 200 to 250 mph. Insulation values are strong as well, typically starting around R-20 depending on the foam used.

The challenge with this system is execution. Shotcrete requires specialized equipment and a skilled crew. Uneven spray application can weaken the structure, and once the concrete skins are applied, there’s little room for design changes or onsite flexibility. Finishing the interior and exterior also requires extra steps, like furring strips or attachment systems for drywall or siding, unlike the built-in web stud system of an ICF wall.

For commercial or large-scale projects, this system can be efficient. For custom home construction, it’s less forgiving and more labor-intensive.

Precast Concrete Panels: Speed Comes at the Cost of Flexibility

Precast panels are poured and cured in a factory, then delivered to the job site and set into place using cranes. These panels are incredibly strong, often rated with compressive strengths between 5,000 and 8,000 psi. When designed correctly, they can resist winds exceeding 200 mph.

Factory production ensures consistency and quality. Walls often include pre-cut openings, integrated insulation, and sometimes even embedded finishes. Once delivered, a home’s walls can be installed in just a few days.

However, precast comes with trade-offs. These panels are heavy and costly to transport, especially to remote areas. Cranes are required to lift them into place, and any changes to the home’s design after casting are nearly impossible. It’s also important to seal joints properly to prevent air leaks and moisture intrusion over time.

A related system, called tilt-up panels, casts insulated concrete panels directly on-site and then lifts them into place. This approach avoids shipping costs but still requires heavy equipment and careful planning.

3D Printed Homes: Fast, Fascinating, and Still Finding Their Footing

3D printed homes use robotic systems to extrude concrete or a similar material layer by layer, following a digital model. It’s an exciting new approach that promises speed, minimal waste, and lower labor costs. In some cases, the structural walls can be printed in just one to two days.

While the technology is evolving quickly, it’s not yet a perfect fit for most custom homes. Many printed systems do not include insulation during the printing process, which means extra work is needed afterward to meet energy codes. Wall strength varies, but current printed homes tend to max out around 100 to 150 mph in wind resistance—below the threshold needed for areas that see severe storms.

These homes are best suited for flat sites with simple footprints. Multi-story designs, steep lots, and traditional exterior finishes still present challenges.

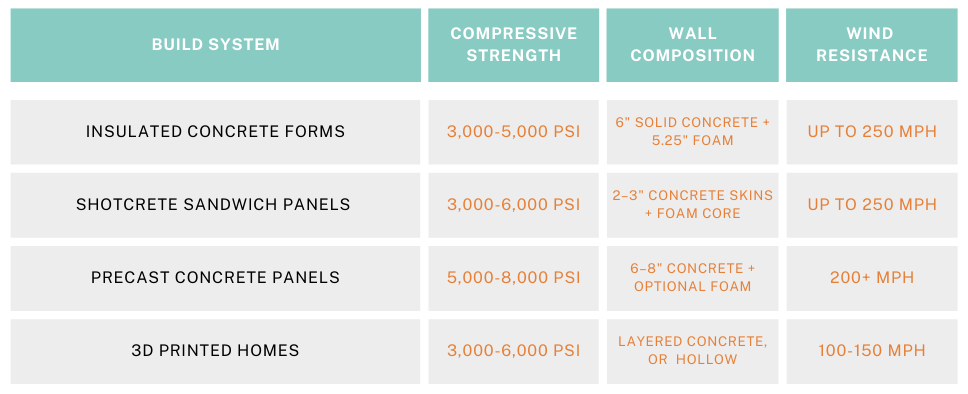

How Do They Stack Up?

Here’s a side-by-side comparison based on key structural and performance metrics:

The Bottom Line

Each of these systems offers major improvements over traditional wood framing. But only one combines structural strength, energy efficiency, and design flexibility in a way that’s well suited to real-world residential construction.

That’s why we build custom homes with ICF construction.

This system doesn’t just perform well on paper—it performs where it matters most. From steep, rocky terrain to wide-open fields vulnerable to storms, ICF is built to handle the demands of life in the Ozarks. These homes stay cool in summer, warm in winter, and calm during severe weather. With wind resistance ratings up to 250 mph, built-in insulation, and long-term durability, ICF offers a peace of mind that wood framing—and even some newer concrete systems—simply can’t match.

If you're planning to build your forever home or just want a smarter, safer structure that lasts for generations, ICF is a solution that delivers on all fronts.

Curious if ICF is right for your project?

We’re happy to walk you through how it compares to other systems, based on your goals, site, and budget.

📞 Contact us to start the conversation. Let’s build something exceptional together!